Introduction:

The RF Capacitance Level Sensor is designed to provide accurate and reliable point level detection for solids (powders and lumps), liquids, and slurries stored in vessels and tanks. Utilizing radio frequency (RF) capacitance technology, this sensor detects the presence or absence of material by sensing minute changes in capacitance caused by the difference in the dielectric constant of the material versus air.

Applications

- Point Level Detection: Suitable for high and low-level detection in bins, vessels, tanks, chutes, and conveyors.

- Process Control: Ideal for managing levels in processes involving plastics, chemicals, coal/fly ash, concrete, food ingredients, pharmaceuticals, feed, grain, mining, foundries, wood, or paper processing.

- Preferred Applications: Effective for solids, liquids, and slurries across various industries.

Key Features

- High Sensitivity: Detects minute changes in capacitance as low as 0.5 pF, ensuring precise level measurement.

- Interference-Free Operation: Designed to operate without interference, providing reliable performance in various conditions.

- Simple Calibration: User-friendly calibration process allows for easy setup and adjustment.

- Fail-Safe Functionality: Ensures safe operation by defaulting to a predetermined state in case of a fault.

- Build-Up Immunity: Engineered to ignore material build-up or coating on the probe, preventing false indications.

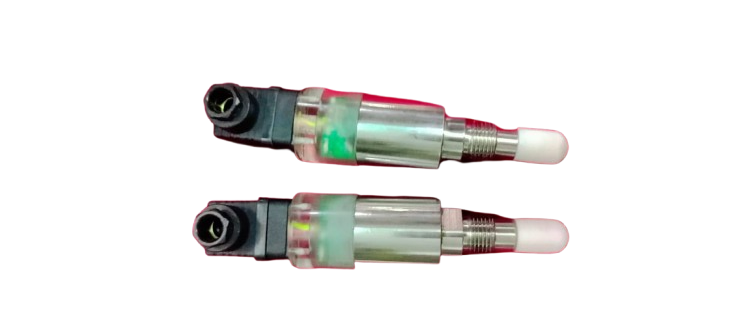

- Robust Construction: Features a stainless steel sensing rod and grounding part for durability and corrosion resistance.

- Versatile Probe Design: Offers different probe configurations to suit metallic and non-metallic tanks, including twin probes and still wells for low-dielectric media.

- Wide Operating Range: Suitable for process temperatures from -40° to +650°C and pressures from -0.2 to 10 bar.

- Flexible Signal Output: Provides 2 SPDT or 1 DPDT relay outputs for integration with control systems.

- Multiple Supply Voltage Options: Compatible with 24 VDC, 110 VAC, or 230 VAC power supplies.

Working Principle

The sensor operates by forming a capacitance between the level sensing probe and the metallic wall of the vessel, which act as two electrodes, with the application media serving as the dielectric medium. As the level of the process material rises, the dielectric value changes, resulting in a change in capacitance between the probe and the vessel wall. This change is detected and measured using RF techniques, and the signals are interpreted by the evaluation unit, converting them into relay output signals. The RF current flowing in the capacitor helps the electronics detect the presence of the application media.