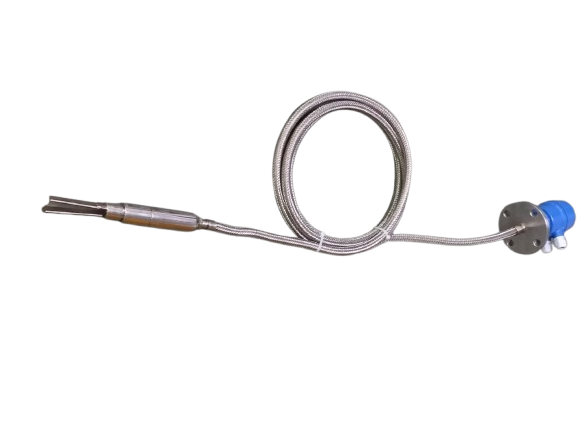

The Flexible Rope Type Vibrating Fork Level Switch is engineered for reliable detection of solid materials across various industrial applications. Its design features a fork-shaped sensor attached to a flexible rope, allowing it to adapt seamlessly to different tank shapes and sizes. The sensor operates by vibrating at a specific frequency; when it comes into contact with solid material, this vibration pattern changes, triggering a signal to indicate the presence of the material.

Applications

- Mining: Monitors levels of bulk solids, such as ores and aggregates, in hoppers and bins.

- Agriculture: Detects feed levels in silos and grain storage facilities.

- Food Processing: Ensures accurate measurement of powdered ingredients and bulk solids in storage and processing tanks.

- Cement and Construction: Tracks levels of cement, sand, and other aggregates in silos and storage areas.

- Bulk Material Handling: Provides reliable level detection for a variety of solid materials in logistics and storage applications.

Key Features

- Adaptable Design: The flexible rope allows for installation in various tank shapes and sizes, accommodating tight spaces.

- Reliable Detection: Accurately detects the presence or absence of solid materials, ensuring consistent monitoring.

- Durable Construction: Built to withstand harsh industrial environments, ensuring long-lasting performance.

- Minimal Maintenance: Designed for low maintenance requirements, reducing operational downtime.

- Fail-Safe Operation: Provides reliable alerts to prevent overflow and enhance process safety.

- Versatile Applications: Suitable for a wide range of industries, including mining, agriculture, food processing, and chemicals.

Working Principle

The Flexible Rope Type Vibrating Fork Level Switch operates on the principle of vibration frequency change. The switch features a fork-shaped sensor that vibrates at a specific frequency. When the fork is exposed to solid material, this vibration frequency is altered due to the material’s presence. As the solid material contacts the vibrating fork, the change in frequency is detected by the electronic circuit within the switch. This alteration triggers a signal indicating the presence or absence of material, which can activate alarms, control systems, or other safety measures. The design allows for reliable operation even in harsh environments, ensuring accurate monitoring of solid levels in various applications. The flexible rope construction further enhances adaptability, making it suitable for different tank shapes and configurations.