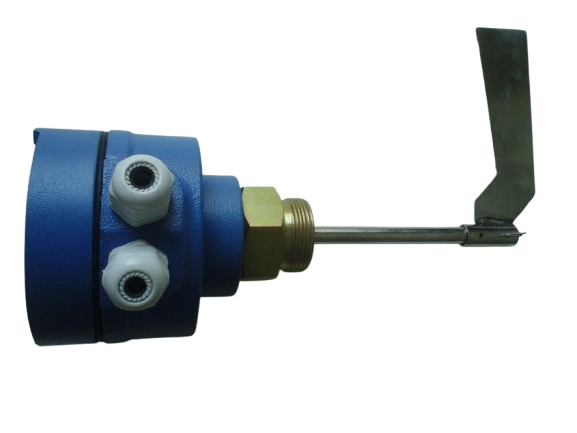

Introduction: The 1 Vane L Type Rotating Paddle Level Switch is a reliable device designed for detecting the level of bulk solids and powders in various industrial applications. It features a single L-shaped paddle that rotates at a constant speed. When the material level rises and obstructs the paddle, the resulting resistance is detected by the internal mechanism, triggering an alert or control action.

Applications:

- Food Processing: Monitoring levels of bulk ingredients such as flour, sugar, and grains in silos and hoppers.

- Agriculture: Detecting levels of animal feed, fertilizers, and seeds in storage bins and silos.

- Cement and Construction: Monitoring levels of cement, sand, and other aggregates in storage facilities and silos.

- Plastic and Rubber Industries: Level detection of granules and powders in mixing and storage applications.

- Mining and Minerals: Detecting levels of bulk materials such as ores and aggregates in processing areas.

Specifications:

- Operating Principle: Rotating paddle technology.

- Paddle Type: Single L-shaped vane design.

- Material: Typically made from stainless steel or durable plastic.

- Process Temperature Range: -20°C to +80°C (-4°F to +176°F) depending on model.

- Process Pressure Range: Up to 6 bar (87 psi) depending on design.

- Power Supply: 24 VDC, 110-240 VAC options available.

- Output Signal: Relay, PNP/NPN, or analog (4-20 mA).

- Response Time: Typically <1 second.

- Mounting Options: Flange or threaded fittings for easy installation.

- Certifications: CE, UL, or other relevant industry standards.

Working Principle: The 1 Vane L Type Rotating Paddle Level Switch operates on the principle of mechanical obstruction. A motor drives the rotation of the L-shaped paddle at a fixed speed. In the absence of material, the paddle spins freely. As the material level rises and contacts the paddle, resistance to the rotation increases. This resistance is detected by the internal sensing mechanism, which then triggers a switch to indicate the presence of material at the specified level. This method ensures accurate and reliable level detection for bulk solids and powders.

Features:

- Robust Construction: Designed to withstand harsh industrial environments.

- Adjustable Sensitivity: Allows for detection of materials with varying densities.

- Fail-Safe Design: Ensures reliable operation even in power loss scenarios.

- Low Maintenance: Minimal moving parts reduce wear and tear.

- Easy Installation: Compact design with flexible mounting options.

This level switch is suitable for a wide range of industries requiring reliable point level detection of bulk solids and powders.