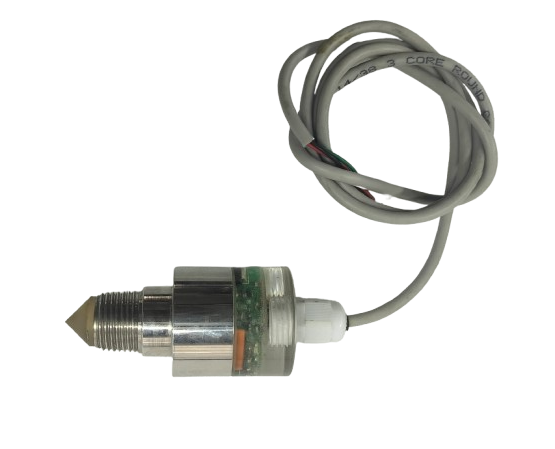

Introduction: The Infra Level Sensor is a non-contact measurement device that utilizes infrared technology to accurately detect the levels of liquids and solids in various applications. By emitting infrared light and analyzing the reflection from the material’s surface, it provides precise and reliable measurements without direct contact.

Applications:

- Water and Wastewater Treatment: Monitoring water levels in tanks, reservoirs, and clarifiers to ensure optimal treatment processes.

- Chemical Processing: Detecting liquid levels in chemical tanks and reactors, facilitating safe handling of hazardous materials.

- Food and Beverage Industry: Measuring ingredient levels in production processes, such as fermentation tanks and storage vessels.

- Oil and Gas: Assessing levels in storage tanks and separators to manage liquid resources efficiently.

- Pharmaceutical Manufacturing: Monitoring liquid levels during various production stages to ensure precision and safety.

- Bulk Material Storage: Detecting levels in silos and bins containing powders or granular materials to prevent overflows and manage inventory.

- HVAC Systems: Monitoring levels of water and other fluids in cooling towers and related applications.

Features:

- Non-Contact Measurement: Utilizes infrared technology to measure levels without direct contact, minimizing contamination risks.

- High Accuracy: Delivers precise measurements for various liquids and solids, ensuring reliable operation.

- Wide Measurement Range: Capable of detecting levels across a broad spectrum of materials and container sizes.

- Robust Design: Engineered to withstand harsh industrial environments, with resistance to chemicals and temperature variations.

- Minimal Maintenance: Designed for long-term reliability with low maintenance requirements, reducing operational downtime.

- Versatile Applications: Suitable for diverse industries, including water treatment, chemicals, food and beverage, and pharmaceuticals.

- Easy Installation: Simple to install and integrate into existing systems, with various mounting options available.

Working Principle: The Infra Level Sensor operates by emitting an infrared beam towards the surface of the target material. When the infrared light strikes the surface, it reflects back to the sensor. The sensor then measures the intensity and time delay of the reflected light to determine the distance to the material’s surface. By continuously monitoring these reflections, the sensor accurately calculates the material’s level within the container. This non-contact method ensures precise level detection while preventing contamination and wear associated with direct-contact sensors.