Our range of Nylon Testing Fixtures is crafted for precision testing of various electrical, electronic, and mechanical components. These fixtures are lightweight yet durable, offering excellent performance in high-frequency testing environments. Designed to meet the demands of industries like automotive, electronics, and manufacturing, these fixtures are non-conductive and highly resistant to corrosion, impact, and wear, ensuring long-term reliability and easy maintenance.

Types of Nylon Fixtures:

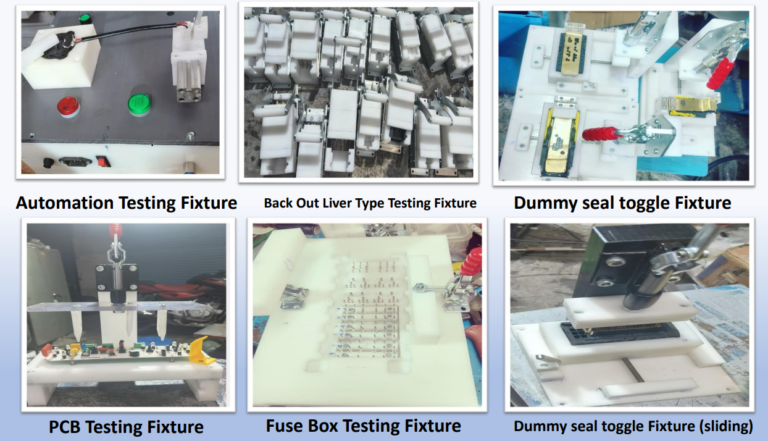

- Automation Testing Fixture

- Built for automated testing processes, reducing manual effort and improving accuracy.

- Ideal for production lines and high-volume testing.

- Back Out Liver Type Testing Fixture

- Designed for testing liver-type components.

- Provides robust clamping for stable and repeatable tests.

- Dummy Seal Toggle Fixture

- Used to test toggle switches and dummy seals.

- Compact and easy to operate in various testing environments.

- Dummy Seal Toggle Fixture (Sliding Type)

- Features a sliding mechanism for smooth and consistent testing of toggle-based components.

- Ideal for repetitive testing with minimal effort.

- PCB Testing Fixture

- Specialized for testing printed circuit boards (PCBs) in production and R&D labs.

- Ensures secure positioning and reliable contact for accurate readings.

- Fuse Box Testing Fixture

- Designed for functional testing of fuse boxes and electrical connectors.

- Reduces testing time while maintaining precision.

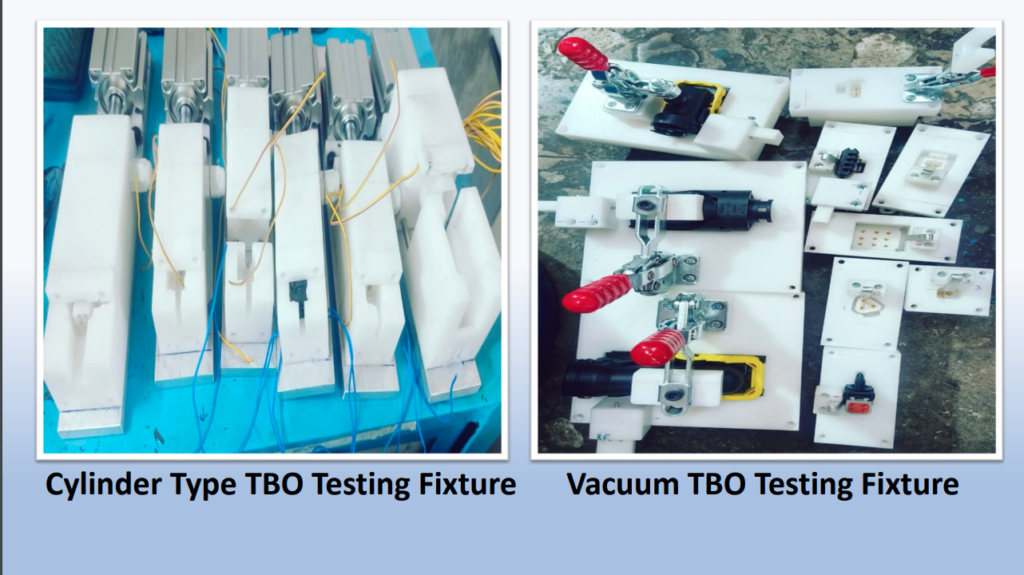

Key Features:

- Durable Nylon Material: High impact resistance and lightweight handling for easy use.

- Non-Conductive: Perfect for electrical testing applications, ensuring operator safety.

- Corrosion and Chemical Resistance: Ideal for harsh industrial environments.

- Customizable: Adjustable designs to accommodate various component sizes and shapes.

- Low Maintenance: Built for continuous use with minimal wear and tear.

Applications:

- Electronics Manufacturing: Testing of PCBs, connectors, and electronic components.

- Automotive Industry: Quality control for fuse boxes, toggle switches, and electrical modules.

- Automation Systems: Integration into automated testing setups for production efficiency.

- R&D Labs: Ideal for testing prototypes and custom components.

- Industrial Electrical Testing: Ensures accurate and reliable results for various electrical systems.

Why Choose Nylon Fixtures?

- High Precision and Reliability: Ensures consistent testing results.

- Long-Lasting and Robust: Withstands continuous use in demanding environments.

- Lightweight and Easy to Handle: Reduces operator fatigue and increases efficiency.

- Wide Range of Applications: Suitable for electrical, electronic, and mechanical testing needs.