Introduction:

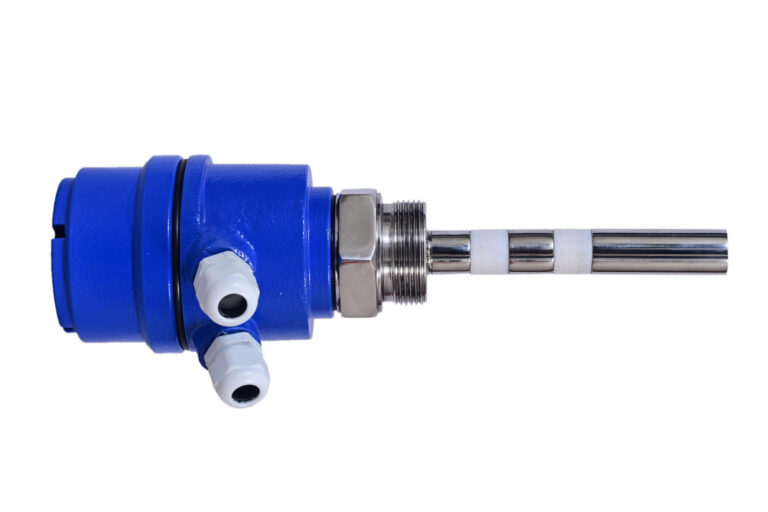

The Standard RF Admittance Level Switch is an advanced sensor designed for accurate level detection of liquids and solids in various industrial applications. It operates on RF admittance measurement, a combination of capacitance and conductance, ensuring precise material detection without direct contact. This non-contact sensing capability is particularly beneficial for handling corrosive, high-temperature, and static-sensitive materials.

Built with a robust design, the switch can withstand extreme pressures and temperatures, making it suitable for demanding industries such as water treatment, food processing, chemical manufacturing, and petrochemical storage. Its high sensitivity enables it to detect even minor level variations, ensuring efficiency and safety in automated control systems.

Applications

- Liquid Level Measurement: Detects levels in tanks containing water, chemicals, and oils.

- Bulk Solid Monitoring: Measures levels of powders, grains, and solids in silos.

- Overfill Prevention: Prevents overflow by detecting high levels in storage tanks.

- Dry Run Protection: Protects pumps by ensuring they do not run without material.

- Interface Detection: Differentiates between layers of liquids, such as oil and water.

- Wastewater Treatment: Maintains optimal levels in treatment plants.

- Food & Beverage Industry: Ensures precise level control in food processing.

- Chemical Processing: Monitors hazardous liquid levels in chemical plants.

- Pharmaceuticals: Ensures accuracy in manufacturing and storage.

- Petrochemical Industry: Tracks liquid levels in storage and distribution systems.

Key Features

- Compact design for easy installation.

- Wide input power supply (15 – 80 VDC & 15 – 260 VAC).

- Low power consumption, making it energy-efficient.

- Simple calibration for user-friendly operation.

- Active shield compensation prevents material buildup on the probe.

- Static charge safe, suitable for fly ash, acids, plastics, and other static-sensitive applications.

- Customizable process connection (Threaded/Flanged options available).

- Remote electronics version available upon request.

- Explosion-proof (Exd) version for hazardous areas (Gas Group IIC, T6 compliant with IEC 60079-1-2007 & IEC 600529-2001).

Working Principle

The RF Admittance Level Switch operates based on capacitance measurement. It consists of a sensing rod and a guard electrode, both interacting with the material in the tank.

- Air Mode: When the sensing rod is exposed to air, the capacitance remains at a baseline level.

- Material Contact: As the liquid or solid rises and touches the rod, the capacitance increases due to the dielectric properties of the material.

- Threshold Detection: Once the capacitance reaches a set threshold, the switch activates, triggering an alarm, controlling a pump, or sending a signal to an industrial control system.

Sensing Components

The RF Admittance sensor consists of:

- Earth Extension (Body)

- Compensation Shield

- Sensing Rod

These components form three capacitances:

- Shield-Earth Capacitance

- Shield-Sense Capacitance

- Sense-Earth Capacitance

A high-frequency sine wave is fed into both the Sensing Rod and the Compensation Shield. The voltage at the shield and sense remains equal, preventing current flow between them. This setup eliminates shield-sense capacitance, ignoring material coatings and ensuring accurate level detection.

Advantages of RF Admittance Technology

- Static level sensing with no moving parts, reducing maintenance needs.

- Insensitive to material buildup, ensuring consistent operation.

- Selective sensitivity, making it reliable for detecting only the desired level changes.

- Highly durable and resistant to harsh environments, including high temperature and pressure conditions.